Robots are being used to take over mundane human jobs or to work alongside humans in many processes. Robots that work in tandem with humans to make their tasks easier or safer are called cobots. Many industries utilize cobots, robots, artificial intelligence, and automation to cut costs, increase workplace safety, escalate and perfect production processes, and ultimately, make our lives easier.

Robotics automation solutions have revolutionized the way businesses operate, providing a range of benefits such as increased productivity, improved quality control, and reduced labor costs. For businesses looking to implement robotics automation solutions Australia is where you will find Diverseco. Diverseco is a leading provider of high-quality and innovative robotics technology.

With a focus on delivering tailored solutions that meet the specific needs of each client, Diverseco’s robotics automation solutions can help businesses in a variety of industries streamline their operations and improve efficiency. From manufacturing and logistics to agriculture and healthcare, robotics automation solutions can be customized to suit a wide range of applications. With their expertise and commitment to delivering the best possible results, Diverseco can help you achieve your automation goals and take your business to the next level.

Want to know what industries are leveraging robotics to make a difference? We’ve got you covered.

Page Contents

Manufacturing

Manufacturing was one of the first industries to adopt robotics. Robots are helping streamline assembly lines, perfect production, and keep employees safe.

Many manufacturing processes include redundant tasks that need to be done at all hours of the day and night in high-production warehouses. When humans are saddled with mundane tasks, they tend to zone out and make errors. They need regular breaks; plus, they can’t be at factories 24/7 to keep assembly lines running.

Foxconn, a company in China, built Apple’s iPhone. On any given day, the factory can produce 500,000 iPhones per day — or 350 new iPhones per minute. Without robotics, it would be impossible to hit the massive amount of products that need to be produced.

Robots also take the place of humans in dangerous manufacturing tasks like lifting heavy objects, welding, or industrial painting (where inhaling fumes is toxic).

While the upfront investment costs of implementing robotics in the manufacturing industry can be high, doing so will help companies save money over time by increasing production throughput and cutting labor costs.

Public Safety

The public safety sector uses robots to take over time-consuming jobs and keep people safe — it’s expected to be a $5.7 billion industry by 2022.

Robots are being used to patrol parking garages and other areas on a daily basis. The robots can check and run license plates, monitor for questionable activity, and scan parking spots to see how many are available.

On a larger and more dramatic level, the public safety industry uses robots to detect and disarm explosives, search dangerous areas before human crews enter, monitor large events with drones for an aerial view, and make exchanges in hostage situations.

AI robots and systems are helping police departments and agencies recreate crime scenes, understand timelines of events, and quickly identify suspects through rapid identification systems.

It doesn’t look like robots will be able to completely take over many jobs in the public safety industry, but they will certainly come in handy for assistance.

Cleaning

Most cleaning methods and procedures are redundant and time-consuming. Giving these tasks over to robots enables faster and more precise cleaning. Robots can be used to clean windows, air ducts, and floors.

Industries such as healthcare, retail, offices, and educational organizations are leveraging robotics and automation.

For many years, retail stores like Walmart have been using autonomous robots to clean their stores. This frees up employees and managers to deal with more pressing matters like helping customers, restocking products, and doing admin tasks. Cleaning robots have sensors on them to avoid running into people and to ensure a spotless floor.

On an industrial level, robots are taking over more dangerous cleaning tasks like industrial tank cleaning. Traditionally, industrial tank cleaning involves humans in protective gear entering the tanks to clean up and remove sludge buildup — all while working in a confined space. This is dangerous in itself, but in many cases, there are harmful chemicals and gas in these industrial tanks as well. Almost every process required for industrial tank cleaning is dangerous, but thankfully, robots are taking over those tasks as well.

When robots are involved in tank cleaning, they enter the tanks instead. However, the robots are remote-controlled by workers off-site, so they are not entirely removed from the tank cleaning process. This allows humans to supervise the work without putting themselves in danger.

Food and Restaurant

In the agricultural stage of food production, robots are used to plant, fertilize, treat, and harvest products. When robots handle redundant tasks, they allow farmers to focus on more crucial tasks of running a business. During the storage and transportation stages, sensors are used to monitor storage containers — this ensures the food remains at a reasonable temperature and isn’t contaminated.

In the restaurant industry, robots are used to seat guests, deliver food, and take orders. With the current labor shortage and COVID-19 regulations in place, robots are filling in critical roles in restaurants.

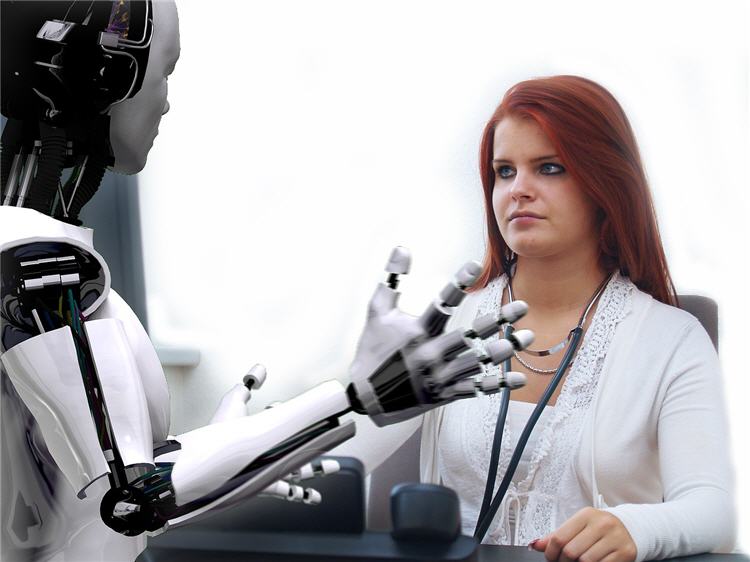

Healthcare

In healthcare, robots are assisting with surgeries, scans, examinations, physical therapy, and early disease detection. Robots also administer COVID-19 tests to limit the exposure between healthcare workers and potential COVID cases.

The healthcare industry is also using robots to deliver and restock supplies and check on patients. When robots take over smaller but crucial tasks, doctors and nurses can see more patients and offer a better experience.

Robotics Will Shape the Future

It’s hard to believe that society is only scratching the surface of robotic technology — it has been around for less than 100 years. It’s exciting to think about what else robots can accomplish.

Mordor Intelligence notes that the robotics industry “was valued at USD 27.73 billion in 2020 and is expected to reach USD 74.1 billion by 2026.” The COVID-19 pandemic boosted the industry but even before that, many industries were taking advantage of the benefits that robots and AI have to offer.

Robots are creating safer work environments, taking over redundant tasks, perfecting processes, and cutting costs.